Discover How Additive Manufacturing Startups impact Your Industry

Curious about new technological advancements in the manufacturing sector? Explore our analysis of 737 global additive manufacturing startups & scaleups and learn how their solutions impact your business!

The additive manufacturing sector is transforming manufacturing operations by accelerating production runs and enabling mass customization. Besides, 3D printing minimizes materials wastage and reduces production costs. That is why manufacturers are integrating additive manufacturing solutions in factories. We give you data-driven innovation insights based on our analysis of 737 additive manufacturing startups & technologies so that you do not miss out on emerging 3D printing solutions. This time, you get to discover 10 hand-picked additive manufacturing startups impacting 10 industries.

Innovation Map highlights Top Additive Manufacturing Startups impacting 10 Industries

For this in-depth research on the Top Additive Manufacturing Startups, we analyzed a sample of 737 global startups and scaleups. These insights are derived by working with our Big Data & Artificial Intelligence (AI)-powered StartUs Insights Discovery Platform, covering 2 093 000+ startups & scaleups globally. The platform quickly delivers an exhaustive overview of emerging technologies within a specific field as well as identifies relevant startups & scaleups early on.

In the Innovation Map below, you get an overview of the 10 emerging additive manufacturing startups mapped to 10 industries they are optimizing. This research provides you with data-driven innovation intelligence that improves strategic decision-making by giving you an overview of emerging technologies & startups advancing additive manufacturing.

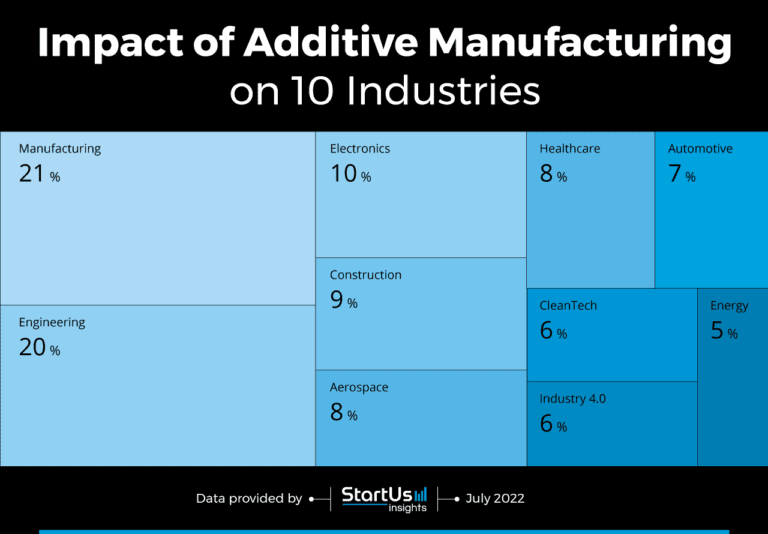

Tree Map reveals the Impact of Additive Manufacturing on 10 Industries

Based on the Innovation Map, the Tree Map below illustrates the impact of Additive Manufacturing on 10 industries in 2022. Each industry benefits from different aspects of additive manufacturing. For example, automotive and aerospace industries utilize the lightweighting features of the technology whereas it emphasizes sustainable operations in the construction sector. However, the most significant aspects of 3D printing in industrial applications are high-speed, low-volume production runs, design and production flexibility, and on-demand manufacturing. That is why the manufacturing and engineering industries see great activity in the 3D printing spectrum. At the same time, electronics, healthcare, and energy industries utilize additive manufacturing to develop intricate components for varying use cases. Lastly, 3D printing in industry 4.0 enables easy automation of production workflows while it advances CleanTech through low-carbon and zero-waste manufacturing.

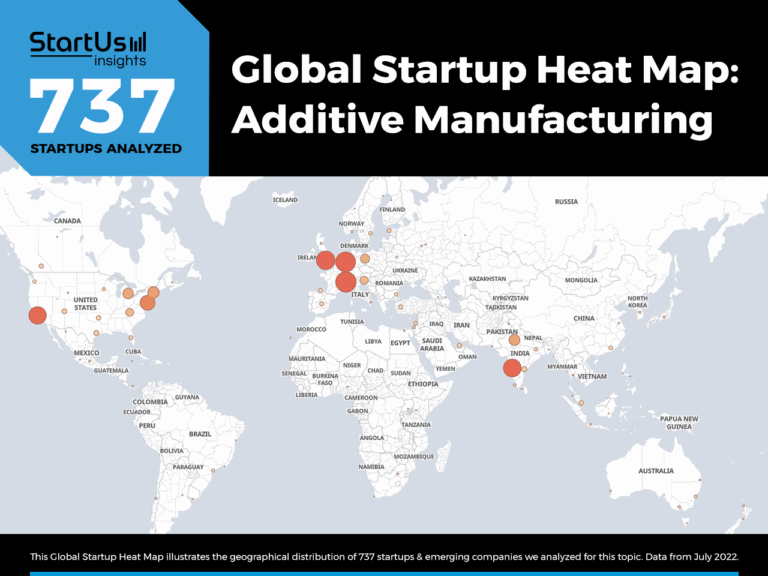

Global Startup Heat Map covers 737 Additive Manufacturing Startups & Scaleups

The Global Startup Heat Map below highlights the global distribution of the 737 exemplary startups & scaleups that we analyzed for this research. Created through the StartUs Insights Discovery Platform, the Heat Map reveals that Western Europe has a high concentration of additive manufacturing startups, followed by the US and India.

Below, you get to meet 10 out of these 737 promising startups & scaleups as well as the solutions they develop. These 10 startups are hand-picked based on criteria such as founding year, location, funding raised, and more. Depending on your specific needs, your top picks might look entirely different.

Impact of Additive Manufacturing on 10 Industries

1. Manufacturing

Additive manufacturing eliminates the need for specialized production equipment and imparts flexibility to manufacturing lines. That is why the manufacturing industry is at the forefront of integrating 3D printing. Besides, it enables profitable and high-speed production runs for low-volume parts as well as obsolete parts. Additionally, additive manufacturing decentralizes production and brings fabrication closer to assembly lines, reducing logistics costs. To accelerate its adoption, startups working in the sector innovate to reduce the entry cost of additive manufacturing solutions and increase print accuracy.

NematX provides Nematic 3D Printing

NematX is a Swiss startup that advances nematic 3d printing. The startup combines liquid crystal polymers (LCP) and its proprietary material extrusion technology to create high-performance parts. They feature better mechanical and thermal properties compared to conventional thermoplastics like polyether ether ketone (PEEK) and polyethyleneimine (PEI). Moreover, the startup’s technology ensures high precision in the printed parts and, thus, improves manufacturing precision.

2. Engineering

Product engineers leverage additive manufacturing to create physical models of part designs quickly. This, in turn, allows them to mitigate high-cost prototyping as well as speed up design revisions. Consequently, manufacturers are able to accelerate the time to market for these products. In-house 3D printers also allow engineers to decouple design for manufacturing (DFM) from part suppliers, speeding up product finalization.

Satori develops a Rapid Prototyping 3D Printer

Satori is a UK-based startup that makes Satori VL2800, a rapid prototyping 3D printer. The startup offers 3d printing software and post-processing solutions, along with Satori VL2800, to speed up product design. Additionally, the software supports generative design to automatically create support for the prints. This allows product designers and engineers to work more efficiently and eliminate costly low-volume production runs for design finalization.

3. Electronics

The electronics manufacturing industry leverages additive manufacturing to optimize circuit design and speed up design. Unlike conventional fabrication processes, it prints the circuit while creating the part that encapsulates the circuit. Moreover, the margin of error involved in electronic 3D printing is very low due to the high precision control of computerized systems. This allows electronics manufacturers to directly print complex and customized circuits into surfaces like flexible films and smartphones. Besides, 3D printing eliminates the need for etching and mitigates chemical usage, making electronics packaging more sustainable.

enovate3D offers Electronic 3D Printing Equipment

enovate3D is a Chinese startup that creates 1-10 micron precision electronic 3D printing equipment. The startup uses precision additive manufacturing, functional materials, and 3D integration to print materials. They include high-performance metal conductive materials, polymers, and ceramic-based materials. This, in turn, allows electronics manufacturers to leverage flexible electronics, advanced packaging, and personalized electronics.

4. Construction

3D printing of concrete elements increases their durability due to the manner of assembly. Moreover, construction using additive manufacturing greatly impacts project completion times, material management, and building design. That is why startups develop extrusion technologies for varying applications in the construction industry such as micro-factories and prefabricated construction. This allows construction companies to reduce material costs, make concrete buildings in dangerous environments, and create modern atypical designs. Since concrete 3D printing reduces material wastage, it enables green construction.

Hyperion Robotics offers Concrete Element Micro-Factories

Hyperion Robotics is a Finnish startup that provides concrete element micro-factories. The startup combines robotics and 3D concrete printing to produce reinforced concrete structures from recycled materials. Construction companies developing infrastructure projects for the energy and mining industries utilize this solution to reduce lead time. It also lowers material wastage during construction and decreases carbon emissions.

5. Aerospace

Aerospace manufacturers utilize additive manufacturing for short production runs of large-scale, intricate aircraft parts. Since part requirements for the industry are mostly small-scale fabrication, the technology reduces massive capital expenses. To aid this, startups offer 3D printing solutions that support high precision and complex structures. This allows aircraft manufacturers to create tailored components without repetitive retooling costs. Additionally, using plastic 3D printed parts facilitates aircraft lightweighting and reduces fuel depletion, lowering the industry’s environmental impact.

Additive America enables Digital Aerospace Manufacturing

Additive America is a US-based startup that offers digital manufacturing for aerospace companies. The startup allows manufacturers and designers to send digital models of metal and plastic components to receive production or prototyping costs. It 3D prints the parts once the designs are confirmed and deliver them to its customers. This allows aerospace manufacturers to eliminate massive capital investments associated with short production runs.

6. Healthcare

The medical industry utilizes additive manufacturing to deliver personalized healthcare for patients and develop medical devices. Besides, 3D printing of medical devices speeds up production and capital expenses. This allows medical device manufacturers to de-risk supply chains and decentralize production. Further, manufacturers and healthcare providers are able to customize implants, prosthetics, and orthotics based on patient requirements, increasing treatment effectiveness. Startups also develop anatomical models to better devise surgical strategies.

Prescrib3d Technologies offers 3D-Printed Medical Implants

Prescrib3d Technologies is a US-based startup that develops 3D-printed medical implants for customizable delivery of antimicrobials. The startup’s patent-pending internal channels allow physicians to deliver antibiotics directly to the infected tissue. Unlike conventional polymethylmethacrylate (PMMA) spacers, Prescrib3d Technologies’ spacer, Selective Targeted Therapeutic Release, ensures constant antibiotics concentration in surrounding tissues. As a result, physicians are able to reduce recovery time for patients with joint replacement infections.

7. Automotive

Additive manufacturing of automotive components facilitates lightweighting and mass customization. Automobile companies leverage both metal and plastic materials to improve vehicle performance. These include additive manufacturing of engine parts, battery housings, cooling systems, and heat exchangers, among others. Besides, this allows vehicle original equipment manufacturers (OEMs) to speed up design revisions. Additionally, part suppliers use 3D printing to develop jigs and fixtures, allowing them to reduce lead times while reducing development costs.

Stelna Designs enables Low-Volume Automotive Part Manufacturing

Stelna Designs is an Indian startup that provides low-volume manufacturing runs for automotive companies. The startup uses additive manufacturing to mitigate high capital expenses associated with short production runs. Besides, using Stelna Designs’ services allow automotive manufacturers to avoid retooling, accelerate prototyping, and extend support for obsolete parts.

8. CleanTech

Unlike conventional manufacturing processes, additive manufacturing significantly reduces material wastage during production. Besides, 3D printers replace numerous equipment in production lines and feature computerized control. This reduces the carbon footprint of manufacturing operations. Additionally, startups utilize additive manufacturing to reuse discarded materials, including organic wastes. For example, many startups reuse faulty products and prototypes to make newer parts, reducing wastage and enabling a circular economy.

f3nice creates Recycled Additive Manufacturing Powders

f3nice is an Italian startup that offers recycled additive manufacturing powders. The startup recycles high-value materials such as high-alloyed steels as well as nickel and titanium-based alloys and produces metal powders from them. Additionally, f3nice’s powders are available in varying sizes for applications based on the size distribution of gas atomization systems. The startup’s materials, thus, allow manufacturers and 3D printers to reduce their carbon footprint and enable a circular economy.

9. Industry 4.0

Integrating industrial 3D printing with other industry 4.0 technologies enables automated production lines. To achieve this, startups offer end-to-end 3D printing workflows that readily integrate into manufacturing plants. This allows manufacturers to run production cycles from 3D designs to final products with minimal intervention. Besides, it increases the flexibility of production runs and enables on-demand manufacturing.

AM-Flow furthers Automated Industrial 3D Printing

AM-Flow is a Dutch startup that offers an automated industrial 3D printing ecosystem. The startup’s hardware and software solutions integrate into existing 3D printing production lines to automate products and processes. For this, AM-Flow combines digital manufacturing, automated sorting, robotic part handling, and autonomous mobile robots (AMRs). This allows manufacturers that leverage additive manufacturing to automate entire production workflows and integrate lean principles.

10. Energy

Novel turbine concepts to increase energy efficiency require complex components with specific materials and geometry. Besides, the high turnaround time for energy industry components increases downtimes. To tackle this, energy companies use 3D printing to develop lightweight and high-performance components. For example, many startups develop 3D printed modular wind turbines which reduce logistics costs and aid turbine deployment. Advances in the field improve precision control, dimension accuracy, and component structural integrity of printed components.

WAAM3D advances Wire Arc Additive Manufacturing (WAAM)

WAAM3D is a UK-based startup that develops RoboWAAM, a wire arc 3D printing system. It combines a 3D printer, sensors, onboard fumes treatment, and automatic deposition environment purging, among others. RoboWAAM also features end effectors that function as a welding torch and provides a local-shielding option, protecting reactive materials from oxidation. Further, the startup’s other solution, Shapetech, leverages interferometric technology to provide real-time geometrical data and this enables better process control. These features allow energy companies to ensure consistent deposition, reduce lead time, and extend component life.

Discover All Additive Manufacturing Startups

Every day, new startups and technologies emerge that improve and transform additive manufacturing systems. These solutions span a range of applications from product development and rapid prototyping to low-volume production runs and mass customization. 3D printing trends are moving towards making the technology more affordable and increasing its print precision, which will increase the market penetration of additive manufacturing across industries. Get in touch to identify specific additive manufacturing startups & solutions that advance your business!