Nematx Launches NEX 01 Liquid Crystal Polymer 3D Printer

The NEX 01 is powered by a motion control system and slicing algorithm that lend it micron-resolution 3D printing capabilities.

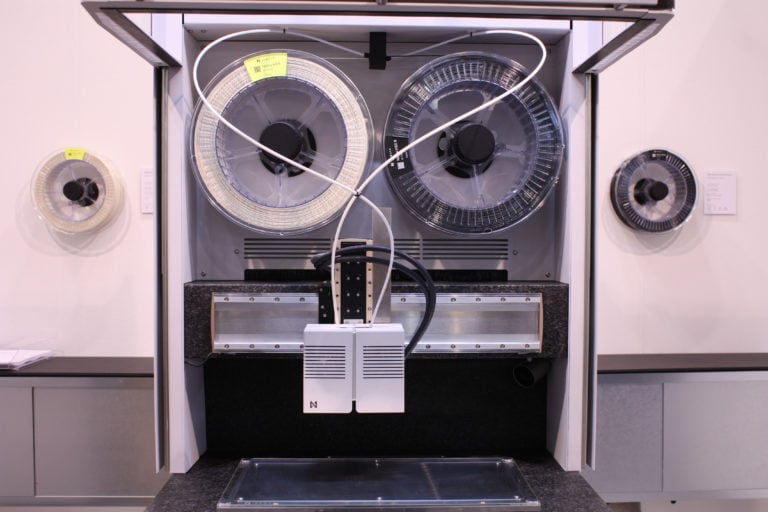

Swiss extrusion 3D printing start-up NematX has launched the NEX 01 3D printer.

Designed to enable high throughput production with process control, the NEX 01 is powered by a motion control system and slicing algorithm that lend it micron-resolution 3D printing capabilities, the company reports. These, in tandem with the machine’s Liquid Crystal Polymer (LCP) compatibility, are said to make it made for meeting industrial applications in demanding production environments.

LCP 3D Printing at NematX

Compared to materials like PEEKs or PEIs, LCPs are made up of shorter, stiffer molecules that are organized in a way that provides them with strength characteristics, according to Nematx. Around these polymers, NematX has developed a Nematic 3D Printing technology. Using fused filament fabrication (FFF), this process aligns LCPs along the print direction, to deliver mechanically-enhanced parts.

Leveraging its technology, NematX can create prints with a Young’s moduli of up to 25 GPa and tensile strength of 650 MPa. NematX won the Formnext Start-up Challenge in 2020, and it has now begun marketing its own range of LCP filaments.

These chemically and biologically inert materials feature low-flammability, high radiation resistance and allow for the production of parts within an accuracy of 25 µm. NematX says it also produces its LCPs to the “highest quality standards” using an in-line monitoring system to control filament diameter and ovality during production.

Sources: Press materials received from the company and additional information gleaned from the company’s website.