ETH Zürich – Feb 23, 2023

3D-printed perfection

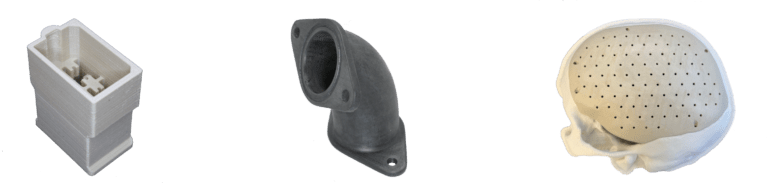

Harsh environments or special industrial use cases require strong and resistant materials in complex shapes. This is what the ETH spin-off NematX specialises in: high-performance polymer 3D printing for applications in space, electronics, or medical applications.

The “Nematic 3D Printing” technology has been developed by Dr. Silvan Gantenbein in the Complex Materials group of Prof. André Studart at ETH Zurich and commercialised together with ETH alumnus Dr. Raphael Heeb. NematX makes liquid crystal polymers (LCP) accessible for additive manufacturing and facilitates the production of ultra-precise parts that are mechanically strong, heat resistant and suitable for use in aggressive chemical or biological environments. LCP represents a novel class of high-performance 3D printing materials whose microstructure can be controlled during processing. The comparatively short and stiff LCP molecules flow easily in the molten state. With a sharp transition from the solid to the liquid state, much more precise and durable parts can be printed from LCP compared to existing engineering polymers for 3D printing. In other words, NematX combines manufacturing precision with mechanical, thermal, and chemical part performance, while other polymer 3D printing technologies typically only offer one or the other.

On the way to outer space

The combination of high manufacturing precision and part performance becomes important for products that are exposed to harsh environments such as in space. 3D printed parts from NematX have already passed space compliance tests after which the young company has been granted access to a flight mission on board the International Space Station (ISS). In addition to the production of lightweight and strong space components, the medium-term goal is to offer in-orbit 3D printing and recycling and to enable more sustainable use of materials and parts in space. The capability of NematX to print complex-shaped items that are lightweight, fully recyclable, and non-toxic is another asset that makes the produced parts specifically suitable for applications in space. Consequently, NematX also participated in the Business Incubation Center of the European Space Agency in Switzerland (ESA BIC CH) that is run by ETH Zurich and that allowed NematX to further develop their products for space and strengthen their connection with ESA.

Die Eigenschaften, die die Nematic-3D-Drucktechnologie bietet, sind auch für andere Industriezweige von besonderer Bedeutung, z. B. für die Medizin und das Gesundheitswesen, wo patientenspezifische, nicht-metallische medizinische Geräte oder Werkzeuge sehr gefragt sind. Flüssigkristallpolymere sind von Natur aus biokompatibel und haben eine hohe Strahlen- und Chemikalienbeständigkeit. Die 3D-gedruckten Teile von NematX weisen eine nahezu perfekte Steifigkeit auf, die dem menschlichen Knochengewebe entspricht. Dies könnte in Zukunft die Herstellung patientenspezifischer orthopädischer Implantate mit voller Röntgentransparenz ermöglichen. Weitere Anwendungsbereiche sind elektronische und elektrische Produkte, Vakuum- oder chemische Komponenten oder Teile der Feinmechanik, die in der Regel besondere Materialeigenschaften und eine hohe Fertigungspräzision erfordern.

The properties offered by the Nematic 3D Printing technology are also specifically relevant for other industry sectors; for instance, medical and healthcare, where patient-specific, non-metallic medical devices or tools are highly sought-after. Liquid crystal polymers are inherently biocompatible with high resistance to radiation and chemicals plus the 3D printed parts of NematX show an almost perfect stiffness match with human bone tissue. This could facilitate the production of patient-specific orthopaedic implants with full x-ray transparency in the future. Other application fields include electronic and electrical products, vacuum or chemical components or precision mechanics parts, that typically require special material properties and high manufacturing precision.

Launch of industrial 3D printing platform

In order to provide a manufacturing solution for the most demanding industrial markets, NematX has designed a high-precision 3D printing platform that meets the highest industry standards and was launched a few months ago. The system called NEX 01 facilitates the manufacturing of high-quality industrial products with minimal material usage and without the need for additional tooling. Hence, NematX takes into account the increasingly important topic of sustainability, all the more because end-of-life products can be readily recycled to produce new raw materials and subsequently new 3D- printed products.

The NEX 01 3D printing platform is already available, and the first machines will be delivered to customers in the second quarter of 2023. In addition, NematX provides customised and comprehensive 3D printing and development services for interested customers.