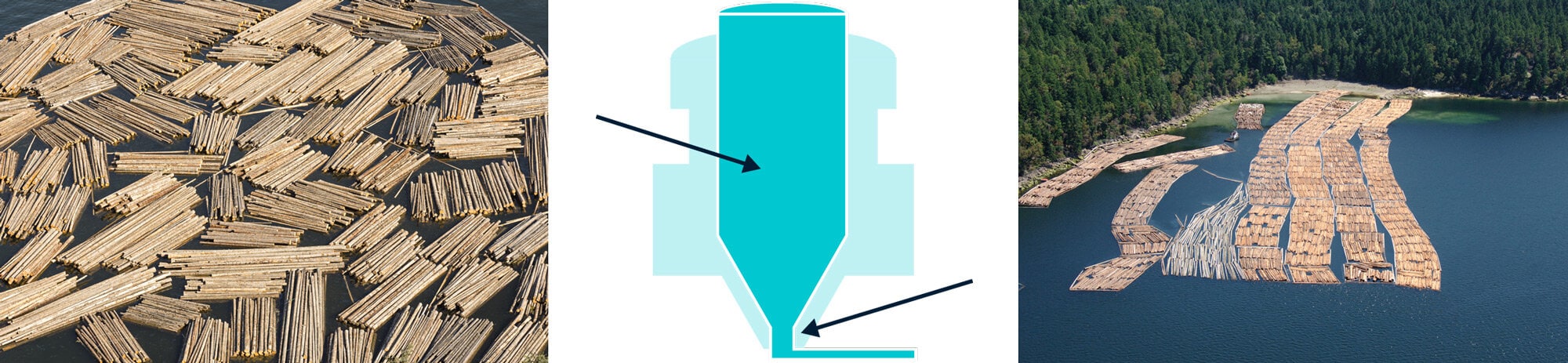

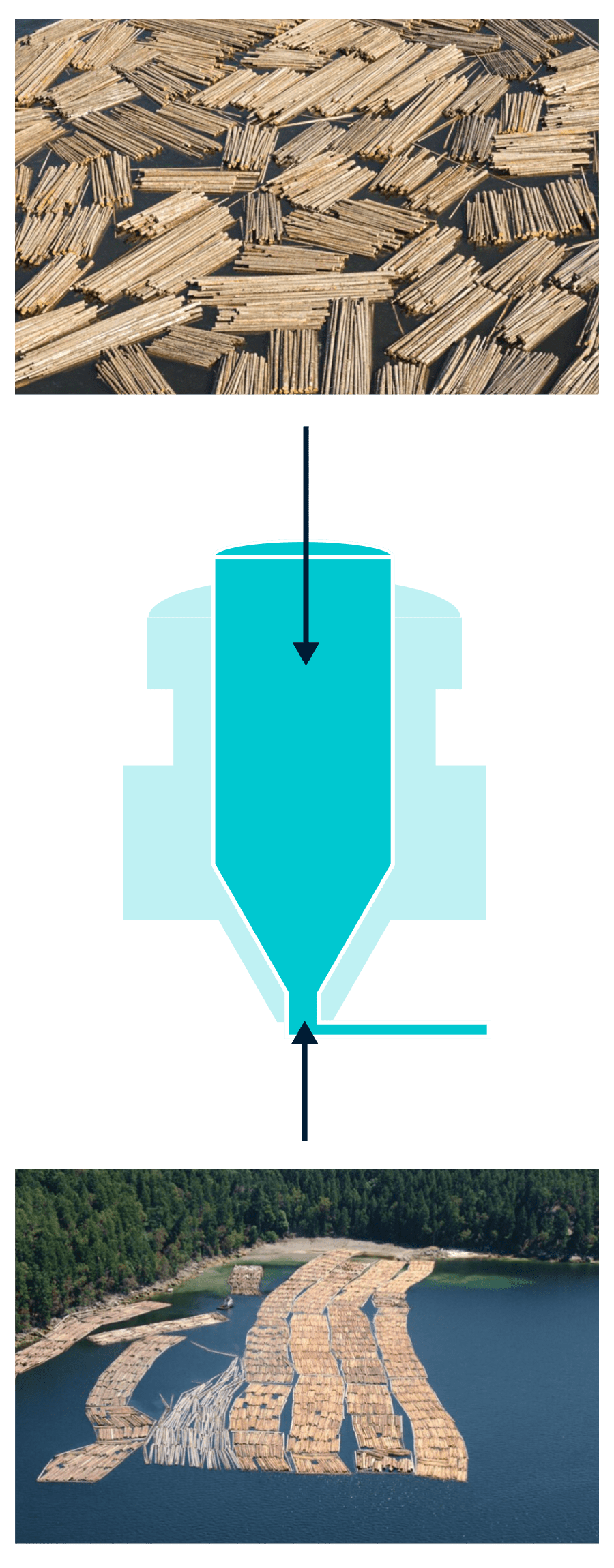

Liquid crystal polymers – short LCPs – belong to the family of high-performance plastic materials. In comparison to conventional thermoplastics such as PEEK or PEI, LCP molecules are comparably short and stiff and possess unique properties that makes their use in 3D printing highly attractive. In the molten state, LCPs adopt a short range order, similar to packages of tree logs floating on a river.

Our proprietary Nematic 3D Printing technolgy is based on material extrusion, using fused filament fabricaton (FFF) or fused depositon modeling (FDM) approach. During printing, we can align these individual packages LCPs along the print direction to produce parts with unmatched mechanical and thermal properties from polymer additive manufacturing.

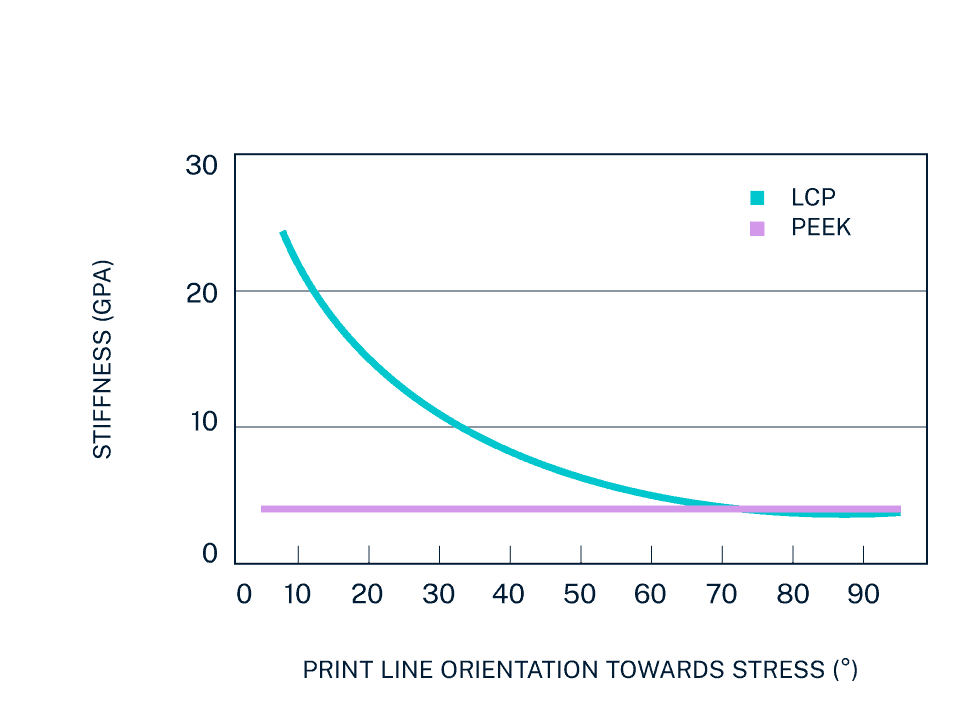

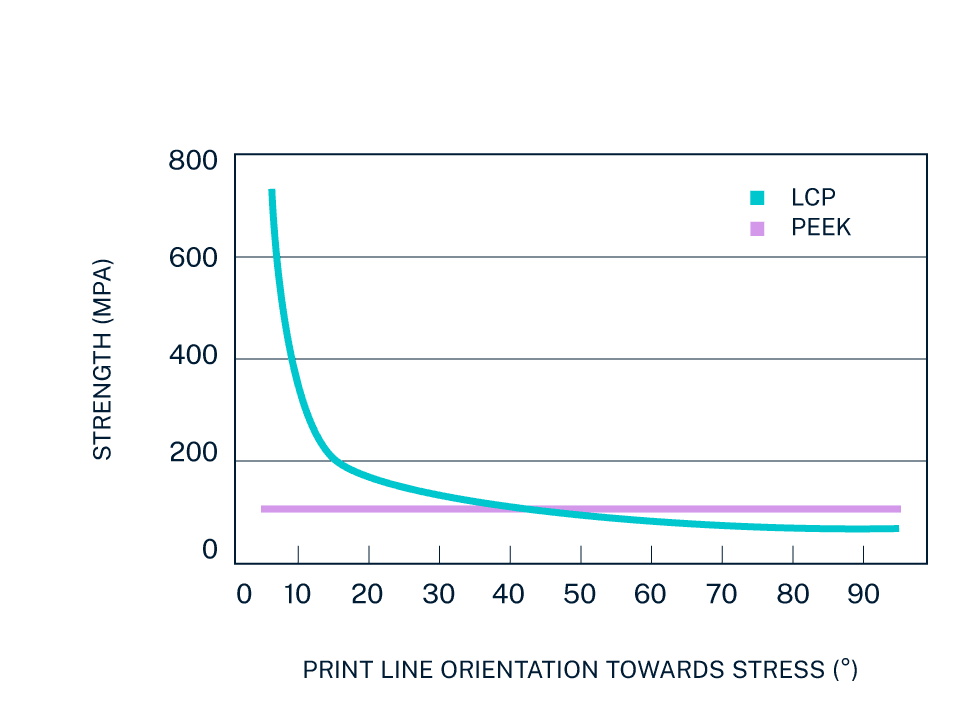

By controlling the molecular alignment of our LCP 3D printing materials, we achieve superior stiffness and strength from polymer 3D printing. In printing direction, we can achieve Young’s moduli of up to 25 GPa and ultimate tensile strengths of 650 MPa. In transverse direction, stiffness and strength values of other thermoplatics such as PEEK or PLA are achieved.

Förrlibuckstrasse 150

CH-8005 Zürich

Switzerland

info@nematx.com

53.403°N / 7.5665°E

Copyright 2025 NematX AG. All rights reserved.

Förrlibuckstrasse 150

CH-8005 Zürich

Switzerland

info@nematx.com

53.403°N / 7.5665°E

Copyright 2025 NematX AG. All rights reserved.